Surgical gowns

Surgical gown materials differ, and understanding the differences and making the right selections can help HCPs make informed decisions, enhance infection control efforts, optimise surgical outcomes and promote patient safety.

Explore our surgical gownsRelated articles

Read all-

Surgical | 1 min read 10% more surgeries performed in Belgium

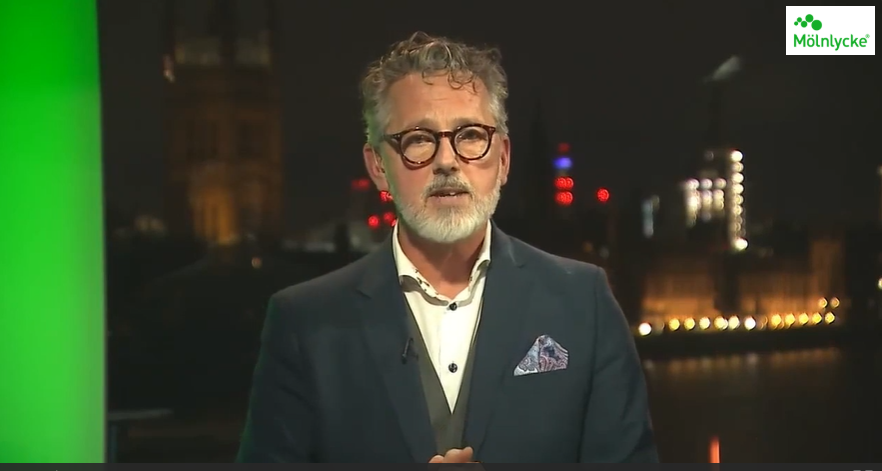

[video section] case berlin Dr Maurice Mommaerts, Maxillofacial Surgeon AZ Sint-Jan Bruges-Ostend hospital It has increased its number of interventions by 10% each year. The staff save time. They also comment on a more pleasant work environment and better patient care. AZ Sint-Jan Bruges-Ostend Av Maxillofacial Surgeon Dr Maurice Mommaerts said: ‘Mölnlycke Procedure trays contribute to a pleasant work environment, less stress and better use of time – in one word, efficiency.’ Director General Dr Hans Rigauts said: ‘Both nurses and doctors who use Mölnlycke Procedure Trays are clearly satisfied with them.’ [Download] case

-

Surgical | 1 min read Tray changes increase procedures by 17% in Finland

[Video section] Finland case Tarmo Martikainen, CEO at Coxa Hospital, Finland Coxa increased the number of procedures performed by 17 percent and incorporated lean processes into its daily work. [download] reference

-

Surgical | 1 min read Navigating the post Covid-19 elective surgery backlog – 12 months on

Recovery has taken a long time, according to the panelists, because healthcare staff numbers have been stretched to capacity even before Covid. Challenges remain with staff fatigue issues, global supply chain surgical equipment sourcing, and continued disruptive waves of Covid. Listen to the full expert panel discussion to gain insights into how the healthcare systems across geographies are managing backlogs and tackling ongoing challenges. [Video section] covid Watch the recent Mölnlycke Talks Online round table discussion, where we catch up with our expert panel who shares their reflections on events since we last met, exactly 12 months ago. Discussed topics: How have the realities of the past year compared with the expectations we had 12 months ago? What have been the key learnings from the last year, that will help us moving forwards How do we balance patient expectations, whilst caring for the health care professionals tasked with tackling the elective surgery backlog How can industry best support you

-

Surgical | 6 min read Find your most efficient OR flow

What makes up the most efficient OR workflow? The optimal OR setup involves not only processes and steps that OR staff take but also how they select, store and set up surgical instruments in the operating theatre. The interplay between how people work and the tools they work with influences how OR personnel find their most efficient flow and achieve increased output. The bigger goal is maximising value: gaining more capacity from OR resources at lower costs, with less waste and greater handling efficiency. Flexible OR efficiency Customised surgical procedure trays enable surgical teams to select all the components they need for specific interventions, which are then packed in a single package. The result helps achieve the greater goal of increased safety and efficiency in the operating room, and significant time, money, and waste savings. OR teams that have adopted ProcedurePak customised trays have achieved: Up to 40% reduction in complete preparation time1 Time savings through need for less preparation time, less opening and set-up time, leading to more procedures being carried out – up to a 37% increase in procedures performed1 Reduced packaging leading to less waste2 -- up to 90% less packaging waste2 3, Reduced product spending and logistic costs1,2 – including up to a 54% reduction in invoicing1 Greater accuracy and consistency for every procedure set-up2 The value of end-to-end handling efficiency Savings and efficiency come throughout the handling process – not just inside the OR. From the moment a surgical team configures their procedure-specific tray, through to stocking and handling, to surgery setup, all the way to invoicing and other administrative and procurement activities, every step creates efficiency and savings. These positive outcomes deliver real value you can calculate. For example, you might use your time savings to increase capacity to perform more surgical procedures. Maybe you will use the extra time to run extra OR staff training and education. Potential value-add areas include sustainability (including environmental, social and governance, or ESG), productivity and risk reduction. The value is real – how you claim that value is up to you. OR efficiency value areas: Sustainability Sustainability is a major driver for change in hospitals and in operating rooms, and the ESG agenda is one that organisations aim to derive value from rather than only seeing compliance as a cost. Adding sustainability to operating room efficiency metrics may make up one of the areas of value you can tap into. With customised procedure trays, you can achieve value from both environmental and people considerations. Up to 90% reduction in packaging waste, optimised stock levels and reduced transport are key contributions to environmental improvements. Considering staff needs, getting value from trays and workflows means facilitating improved ways of working, giving OR personnel more time to focus on patients and the things that matter most, and reducing employee stress. ProcedurePak trays simplify OR teams’ work2. OR efficiency value areas: Productivity Every healthcare organisation is under pressure to deliver more with less – safely. Particularly during periods of significant backlogs. How can hospitals reimagine surgical scheduling? Boosting OR capacity and productivity in challenging conditions is a challenge. But up to 70% of OR staff in a UK survey of 500 healthcare professionals4 agreed that customised procedure trays support improvements in operating theatre efficiencies. With ProcedurePak, you can increase the number of procedures you perform by up to 37%1, increasing the capacity of existing OR resources. Procedure-specific trays can also improve cost control per intervention. In more administrative and logistical terms, custom procedure trays can add value by reducing overtime, simplifying invoicing and tracking, and making order and delivery processes smoother and easier. OR efficiency value areas: Risk reduction Healthcare professionals are working under a great deal of pressure, and staff turnover and burnout are significant issues. Working with fewer resources and the requirement to spend substantial time on non-value-adding tasks such as picking and unwrapping individual components and other similar preparatory and clean-up tasks, surgical staff face a number of challenges that can all create risk in the OR. As both surgeons and operating room staff are forced to conduct more procedures with less resources, risk rises. Streamlining the OR workflow with customised surgical procedure trays, though, can contribute to easing staff stress and risk reduction. By requiring fewer packages overall, and saving time and effort in picking, handling, and opening packages, there is less risk of picking errors and less OR foot traffic. These steps lead to increased quality and cost control because the handling and logistics workflow is simplified and more easily managed. Achieving OR efficiency: You’re not alone With Mölnlycke, you’re not alone in starting and accelerating your OR efficiency journey. Taking a consultative approach, Mölnlycke works together with you as a partner to ensure that you achieve the greatest efficiency possible both from adopting ProcedurePak trays and through your OR workflows and practices. Partnership to find your flow and gain greater value How can you reach maximum value and efficiency in your OR? How can you increase output and see time, monetary and environmental impacts? You can influence these factors by finding your flow in the OR. We are here to help. Based on a process designed by the Institute for Workflow Management in Health Care (IWiG) in Germany, we offer a value report based on your specific situation. The report draws on several processes that examine materials management in the OR to help achieve greater time savings and process efficiencies. The value report generated provides an analysis of potential efficiencies and value gains, looking at your current surgical trays and comparing them against ProcedurePak trays customised for specific interventions. With Mölnlycke by your side, you can: Tap into more sustainable processes for both the environment and people/staff, including everything from quantifiably reduced waste and optimised stock levels to reducing staff stress and facilitating more time for focus on patients Protect and increase productivity, increasing the number of possible procedures, improving cost per intervention and simplifying processes Reduce risk, increasing the efficiency of logistics, and cutting down the risk for picking errors, risk due to the handling and opening of more packages and more. With value built in every step of the way, you can increase output with trays – not just in the operating room but throughout the hospital. We can show you how to get there, offering: Partnership in reviewing your current approach, capturing stakeholder insights, defining KPIs, identifying efficiency opportunities, applying expert advice and recommendations and formulating a tailored proposal and implementation plan. Support with evidence-based solutions, regular progress updates and check-ins to ensure opportunities and blockers are identified, full implementation assistance, training and education, and access to the self-serve Mölnlycke Portal. Partnership reviews and performance against KPIs, sharing of best practices, alignment and collaboration with other hospitals. [Card collection] image card link

-

Surgical | 4 min read Increase OR efficiency by supporting healthcare workers

Operating room optimisation crosses a number of disciplines – from improving turnover time in the operating room to achieving operating room efficiency metrics, from managing OR inventory to precision time management in the OR, from waste management to broader concerns about sustainability initiatives in the operating room, there are multiple dimensions to increasing OR efficiency. Successfully optimising the OR for the perioperative experience means supporting healthcare workers with best practices, processes and tools that support healthcare managers’ ability to do more with smaller hospital budgets and carry out more OR procedures in more efficient ways – all without compromising on quality or safety. OR personnel and healthcare managers tell us that a number of challenges make their work more difficult. First and foremost, preparing for surgery, collecting the right components and surgical instruments and equipment in the operating room, and cleaning up afterwards, are the costliest and time-intensive activities in the OR. Additional challenges stretch resources even further, such as: increasing numbers of procedures and pressure to do even more complex procurement processes cutbacks in material management understaffing overtime costs. Quantifying challenges in the OR Supporting OR efficiency is one key to supporting OR personnel. Cutting back on time spent dealing with surgical instruments and components can significantly improve efficiency in the OR. Traditionally, nurses have needed to collect everything from the storeroom and set it all up for each procedure. Other necessary steps to get the components in place, such as stock-taking, ordering, warehousing and transportation take additional time¹. With healthcare professionals spending a lot of time setting up procedures – up to 30 minutes² in some cases – operating rooms themselves aren’t used to their full capacity. Because they’re spending so much time managing, unpacking, stocking and restocking surgical equipment, they have less time to spend on carrying out procedures and caring for patients. This causes unnecessary stress. And that leads to poor job satisfaction, making it hard to recruit and retain skilled surgical staff. Supporting effective operating room inventory management can improve these metrics as well. Increasing OR efficiency Hospitals and healthcare managers around the world are finding better ways to improve internal processes to save time and increase efficiency in the operating room. Their goals include improving outcomes while ensuring quality and safety. That involves making best use of the resources they have, easing the stress on healthcare professionals so they can perform at their best, and maximising the use of OR so more procedures can be carried out. Procedure-specific trays Customised surgical procedure trays are tailored specifically for the needs of the OR staff in that hospital, dealing with that specific procedure. Procedure trays ensure that staff have the right tools at the right time, all in one convenient package. They simplify the OR team’s work and have been shown to improve operating room efficiency: by saving 40-59% of time during set-up, hospitals can complete more procedures¹ by freeing up time for staff: the more components included in a single tray, the more time is saved across the entire OR process, from ordering to waste removal because no components are wasted and less packaging is required, component handling is more cost-effective and efficient by giving hospitals control of their own stock – hospitals have more ownership of the process and insight, enabling them to forecast more precisely Staff can spend a lot of time searching for the right equipment for each procedure. Managing and storing stock is also extremely time-intensive. But if it’s well-organised, there are opportunities for efficiencies – reducing the time spent on preparation and change-over between surgeries and on stock management. Solutions include colour-coding trays. This gives anyone handling them an easy visual identifier – so that they can store trays in a more organised way, notice when stock is getting low and replenish it, and pick trays before surgeries. It also means that all hospital staff can collect trays. Efficient component management Surgical requirements and protocols are always changing. And surgical components can be wasted when too much is ordered, creating further inefficiencies. Space is at a premium in busy hospitals too. As a result, many hospital managers are introducing lean stock management processes. By planning deliveries of surgical equipment according to demand, they can reduce waste and cost. And they can be sure they always have the right components for the right procedures at the right time.

-

Surgical | 4 min read Surgical instruments for laparoscopic procedures

Patient outcomes and efficiency are dual drivers in the O.R. Laparoscopic surgery types, for example, are designed for safety and efficiency. And ensuring efficiency at every step is making sure that the instruments used in laparoscopic surgery are readily available to the surgical team when they need them. With surgical teams focused on the patient and getting the best outcome, they should not need to think about whether they have the right laparoscopic surgery tools on hand. Instead, everything they need for the complete surgical procedure could be bundled together, saving a significant amount of preparation time. Teams can focus on the patient instead of assembling the materials and components required¹, unwrapping single-packed instruments that could easily have been bundled together in a single sterile procedure pack. Laparoscopic surgery instruments – Customised procedure trays Surgical procedure trays built to your specifications offer the full range of surgical instruments and components your team needs for each individual procedure. Whether it’s laparoscopic surgery or gynecological surgery instruments your team needs, your procedure tray is customised for you, by you, for your specific procedure, your operating room and workflows/practices. All high-quality products, packed into convenient, cost-effective and easy-to-use procedure trays that save time and costs and help to reduce the possibility of error. Mölnlycke ProcedurePak trays are customisable, drawing from a full range of laparoscopic and gynecological surgery instruments to match your every surgical need. How safe is laparoscopic surgery? Why is laparoscopic surgery better than standard open surgery? Laparoscopy, also known as keyhole surgery, is less invasive, using smaller incisions, making it a viable choice for shorter procedure duration, faster patient recovery times and greater patient safety and less risk of infection. With laparoscopy, increasingly precise dissection is possible, making these surgeries more efficient for surgical teams and more favourable in terms of recovering from laparoscopy for patients. The less invasive the procedure, the swifter the patient’s journey to healing. What types of laparoscopic procedures and instruments? Laparoscopy is used to treat and diagnose conditions. Using only small incisions, a small camera, and a variety of specialised laparoscopic instruments, surgical teams can use laparoscopy to remove organs, repair hernias, perform hysterectomies and other gynecological surgeries, and much more. Common laparoscopic surgery types include cholecystectomy (gall bladder removal), colectomy (colon surgery), hernia repairs and gyn surgery (a commonly used term for gynecological surgery), all of which employ laparoscopy-specific instruments. What instruments are used in laparoscopic surgery? As laparoscopic procedures have become more common, the ability to offer minimally invasive surgery has changed the way operations are done and what kinds of laparoscopic surgery instruments are needed. Different laparoscopic surgeries require different instrument types and sizes, which are available as single-packed items or as a part of a procedure-specific laparoscopic instrument tray. From procedure-specific laparoscopy drapes for effective draping to sterile retrieval bags indicated for the quick and safe retrieval and extraction of tissue specimens, a comprehensive range of laparoscopic components is available. The full range of laparoscopic surgery tools for specific procedures is also available, including laparoscopic monopolar scissors, other monopolar instruments such as the L-hook electrode used for laparoscopic endoscopy and monopolar electrocautery, plume evacuation pencils for clearing the operating field of surgical smoke, high-pressure pulsed lavage solutions for cleaning bone and removing debris during joint procedures, suction and irrigation sets to help flush blood and tissue debris from the surgical site to aid visualisation during minimally invasive laparoscopic gynecologic, general, thoracic and urology procedures, ergonomically designed trocars for access to the peritoneal cavity, and Veress needles for creating a pneumoperitoneum. Choose your laparoscopic surgical instruments Get in touch today to discuss your laparoscopic instrument needs, and Mölnlycke can help you select the surgical components you need to build customised ProcedurePak trays for the laparoscopic procedures in the surgical range.

-

Surgical | 4 min read Understand your CO2 impact and drive your sustainability journey

The last thing on your surgical team’s mind when hard at work in the OR is probably how much waste your single-use surgical instruments and drapes generate, or how much more efficiency you could gain from customised procedure-specific surgical trays. But as sustainability becomes a watchword for every industry, the single-use nature of antiseptic surgical environments is also coming under scrutiny by regulatory bodies and even by patients. While patient safety leads as the most important consideration, hospitals continue to be beset by resource limitations balanced against new regulations that demand more sustainable and circular operations. Add to this equation the difficult-to-calculate environmental aspects of the operating room: from the CO2 expended in sourcing and producing the materials used in the production of OR goods to calculating the logistics of getting surgical trays and drapes and other surgical equipment into the hospital and properly distributed. But what if you could gain clarity on exactly what impact the CO2 from your surgical business generates? Sustainability roadmap Mölnlycke Health Care launched WeCare, the company’s 2030 sustainability roadmap, in 2021. The roadmap charts the actions the company is taking toward a sustainable future and supports the objectives of the Paris Agreement on climate change and the UN Sustainable Development Goals (SDGs). WeCare builds on three pillars integral to Mölnlycke’s business approach: Green mindset, Responsible relationships and Ethical business. These pillars influence Mölnlycke’s business models, partnerships, resource management and innovation, and state how Mölnlycke strives to create a work environment where everyone can excel. The WeCare program supports the company’s sustainable growth and determination to take a lead in sustainable healthcare and outlines the short and long-term targets that will ensure our progress, tracking it according to Global Reporting Initiative (GRI) standards or internal KPIs. These targets include a number of key measurable outcomes within the three pillars. For the green mindset, for example, we will become a net zero company by 2050, 100% fossil-free electricity use at manufacturing sites by 2024, zero waste to landfill at manufacturing sites by 2030, and more. For responsible relationships, we will provide a healthy, safe workplace for an engaged workforce, including a long-term target of zero injuries, gender oarity at director level and above by 2025, five different nationalities in executive leadership by 2025, and more than 10,000 lives improved with our global CSR program by 2025, among other goals. Finally, for ethical business, we act with integrity to ensure that 100% of employees receive annual training or awareness in the ethics and compliance space by 2023, that 100% of employees feel safe reporting concerns without fear by 2025, and that 100% of active distributors have completed our due diligence process by 2025. Guiding the conversion to sustainability Our own commitments and verifiable results illustrate our credibility in developing and supporting sustainable healthcare solutions and offering support and consultancy to our customers to help achieve sustainability through our partnership. Specific tools and standards can help to ensure that healthcare organisations can also achieve these ambitious targets. Sustainable standards: ISCC-certified solutions Mölnlycke continuously innovates to offer the most sustainable solutions without compromising on the safety and quality of its products. By applying lifecycle thinking to existing products, the company proactively steers its product portfolios towards improved sustainability outcomes. International Sustainability and Carbon Certification (ISCC) sets of universal drapes and a range of surgical gowns offered by Mölnlycke are one example of more sustainable, circular solutions and our commitment to using materials more efficiently. One of the three layers that make up the drapes is made of ISCC-certified renewable, biobased raw materials. As a result, an externally reviewed Life Cycle Assessment 1 showed these drapes to generate on average 20% less greenhouse gas emissions than traditional products. Calculating a more sustainable footprint Creating products that fulfil sustainability goals is one dimension of the issue. Detailing exactly how these products fulfil sustainability targets is another challenge. To help calculate the advantage, Mölnlycke has developed a digital CO2 measurement tool that calculates the environmental benefits of choosing an ISCC-certified drape over a traditional product. Mölnlycke currently offers approximately 20 ISCC-certified drapes, consisting of up to 30% bio-based material. Demand for products using renewable, bio-based raw materials is particularly high in Scandinavia, the UK and Benelux, and is increasing in other markets as well. The calculator’s model includes the product’s entire life cycle, including Scope 1, 2 and 3. We are transparent about our impact on the environment, people and society and want to support our partners to do the same.

-

Surgical | 10 min read Infections in the operating room

Healthcare providers are under constant pressure to reduce costs and increase efficiency to improve standards of care while also preventing cross-contamination. Maintaining both HCP and patient safety depends on following aseptic procedures in the operating room, and even then, infections in the operating room still happen. Healthcare-associated infection (HAI) is a major health and economic issue, and surgical site infection (SSI) is a major contributor. The rate of SSI is influenced by a number of different factors. Microorganisms, such as bacteria, viruses and fungi can potentially contaminate the OR environment through HCPs and staff clothing or surgical equipment or instruments. OR staff behaviour is also an influence; breaks in sterile technique, such as improper hand hygiene, failure to maintain a sterile field, or a glove breach, can increase the risk that pathogens be introduced into the surgical site. Despite protocols, infections remain a major concern in the surgical environment. SSIs can lead to a requirement for more care, meaning prolonged hospital stays, staff time, additional medication, devices, energy use and possibly further surgical interventions, which all increase healthcare costs and mortality while also being less sustainable. Infection incidence It is estimated that one out of every 20 patients undergoing surgery will develop a surgical site infection (SSI)1 and staff exposure rate to patient’s blood during surgery is as high as 10.4 per 100 procedures2. It’s important to ensure patient safety in the operating room (OR) and to protect healthcare professionals from infection from bloodborne illnesses. In Europe, surgical site infections affect half a million people every year and represent an additional cost of 19 billion euros3. Infection exposure Healthcare professionals are frequently exposed to pathogens. Needlestick injuries, of which there are an estimated one million in Europe each year4, put them at risk of contracting bloodborne illnesses, including hepatitis B, hepatitis C and HIV from patients’ blood. The burden of surgical site infections Surgical site infections are costly to treat; they also cause pain and trauma to patients. An SSI could, for example, mean that a patient goes on to develop a deep tissue infection, which results in the patient having to remain hospitalised for a longer period of time, requiring more staff time, medication, devices, energy use and potentially further surgical interventions, and all of these have an environmental impact and could all have been prevented. SSIs are caused by bacteria that get in through incisions made during surgery. The microorganisms enter by one of the following: From the skin of patients From the surgeons and other operating room personnel From the air From contaminated surfaces or instruments used during surgery5 Preventing SSI isn’t easy. For example, it’s estimated that about one-third of the population naturally carries the bacteria, Staphylococcus aureus, on the skin and in the nostrils6. Some strains of this bacteria (e.g. methicillin-resistant Staphylococcus aureus, MRSA) are multidrug-resistant organisms. Both staphylococci and enterococci bacteria can survive for days to months after drying on commonly used hospital fabrics and plastics7. The air is also a source of potential contamination. Humans shed thousands of skin scales every minute8, each potentially carrying bacteria (80% of bacteria come from the air9). Gloving to prevent infection Preventing infection and cross-contamination in the OR involves considering the air, patients, staff, equipment and surfaces. We collaborate with healthcare professionals to find the most efficient ways to prevent infection and cross-contamination. [Image Section} gloves Surgical gloves Single gloving: Surgical gloves help reduce the risk of infection for both healthcare professionals and patients10, 11 – and are one of many factors that work together to prevent contamination in the OR10. But if a glove is punctured by a needle, the protection is lost and the hole may not be visible. There is an increased risk of SSI when gloves are punctured11. Glove powder may be used to make it easier to put on and take off surgical gloves. But it can trigger reduced resistance to infection, bacterial environmental contamination, foreign body reaction, delayed wound healing, adhesion formation and granuloma formation12, 13. All of these potential consequences can increase the risk of SSI14 . Double gloving with puncture indication: Double gloving with a puncture indication system – wearing both overgloves and undergloves – enables the healthcare professional to see a glove puncture as soon as it occurs. This means they can quickly change gloves and continue the procedure without compromising protection from cross-infection15, 16. In a study of gloves used in surgical procedures, the rate of detection of perforations during surgery was 90.2% with the indicator gloves sub-group, compared to 23% and 36.0% with the combination (two regular) gloves and single gloves sub-groups, respectively15. The practice of double gloving is proven to reduce the risk of needlestick and other sharps injuries and exposure to bloodborne infections. A 2014 Cochrane Review concludes that double gloving reduces the risk of an inner glove perforation by 71%, compared to single gloving16. Leading authorities now recommend double gloving for invasive surgeries: Centers for Disease Control and Prevention (CDC)17 National Association of Theatre Nurses (NATN)18 Association of periOperative Registered Nurses (AORN)19 American College of Surgeons (ACS)20 Royal College of Surgeons of England18 Australian College of Operating Room Nurses18 Preventing infection with staff clothing Staff clothing plays a key role in infection prevention – through protecting patients and OR staff from contamination and supporting clean air in the OR. [Image Section] clothes Multi-patient (reusable) scrub suits Traditional, textile scrub suits are washed between surgeries and reused. However, the use of multi-patient (reusable) textiles raises concerns about the effective cleanliness of the laundered clothing and potential risks from lint production, human health and safety concerns, and environmental impact. Cleanliness of multi-patient scrub suits Stains, wear and tear, and invisible dangers like bacteria can compromise protection and quality of performance. Firstly, can effective laundry facilities be guaranteed, whether the facility is in-house or delivered by a third party? Often, laundry facilities harbour pathogens even in clean environments, leading to recontamination after disinfection. In one study, an epidemiologist determined that the laundry was a potential unrecognised vector of hospital-acquired infections21. The difficulty of effectively removing recalcitrant bacteria, such as clostridium was demonstrated in a large academic university hospital in the United States. It was determined that high levels of CDIFF existed both in their dirty and clean areas of the laundry as well as on delivery truck handles transporting processed textiles back to the facility22. Increased risk of airborne particles due to laundry comes from lint production. Airborne particles increase the risk of SSI, and lint contamination of surgical wounds contributes to other complications, such as thrombogenesis (blood clots), infections, amplified inflammation, poor wound healing, granulomas, adhesions and capsule formation. Health and human safety of multi-patient scrub suits Occupational health is a critical component of sustainability, and by extension, a key part of ensuring occupational health and human safety is reducing the risk of exposure to contaminated material for all staff. With multi-patient (reusable) textiles, laundering reusables poses occupational health and safety risks23, for wearers, patients and laundry staff alike. Hospital laundry workers, for example, handle reusables repeatedly and are at risk of exposure to contaminated material and infection in hospital laundry facilities. Environmental impact of multi-patient (reusable) scrub suits Multi-patient (reusable) scrub suits also have a clear environmental impact. The environmental footprint of laundering reusables includes water consumption24, AMR pathogens entering wastewater25, and biocides and detergents entering wastewater. In addition, laundry facilities require a great deal of hot water, which consumes a lot of energy. In fact, the laundry consumes approximately 50-75% of the total hot water generated in a hospital26. Finally, laundry transport and delivery functions also contribute to CO2 emissions. Single-patient (single-use) scrub suits Single-patient (single-use) scrub suits contribute to hospital infection control measures. Polypropylene scrub suits in particular are associated with significantly lower air and wound bacterial contamination than conventional cotton shirts and trousers27. Wearing single-patient scrub suits ensures that the wearer has a new, quality-controlled product every time. There is no risk of damage or contamination from previous use. Clean air suits Ultra clean air in the OR is achieved by a combination of laminar air flow, the number of door openings, the number of people in the OR and clean air suits. It’s particularly important in orthopaedic, implant and paediatric interventions. Clean air suits are especially designed to reduce contamination from airborne microorganisms by staff. They have a better protective effect than a multi-patient (reusable) system made of cotton/ polyester, giving high resistance towards bacterial penetration28 even when ordinary ventilation is used in the OR29. Preventing contamination from the patient’s skin Surgical drapes and whole body washing can prevent microorganisms from the patient’s skin from contaminating the surgical wound and causing SSIs. [Image Section] p-tray Surgical drapes Surgical drapes prevent the transfer of microorganisms from the patient’s skin in surgical procedures. Impermeable materials control infection, while effective fluid control allows for a drier working area. The most effective drapes have fewer parts and are easy to use – to reduce the risk of contamination. Washing the skin Whole body washing reduces the skin bacterial load and ultimately decreases the risk of SSI. There are a number of ways to clean the skin: Soap and water: the typical standard patient-cleansing procedure. But this simply spreads the organisms, releasing the bacteria over the surface of the skin from the naturally heavily colonized areas30. Povidone iodine: preoperative body washing with povidone iodine provides some protection. But surgery-associated products like blood, bus and fat make it less effective31. Chlorhexidine digluconate solution: in several studies, a chlorhexidine digluconate solution has been found to prevent healthcare-acquired conditions in intensive care settings32. Recent surgical protocols recommend patients shower twice with chlorhexidine digluconate solution before surgery, waiting at least one minute before rinsing it off33. It’s also less likely to cause skin reactions than alternatives34. Reducing potential infection vectors with surgical procedure trays In addition to increasing efficiency and convenience, surgical procedure trays like ProcedurePak reduce the potential for introducing additional sources of microorganisms in the OR35. All the components, surgical instruments, and procedure-specific surgical drapes and gowns required to perform a surgery are contained within a single package. The pack forms the basis for not only less preparation time, less opening and set-up time³⁸ but also to reduce the risk of contamination in the OR due to less packages to open³⁹. All-in-one and single use ProcedurePak is designed to include every single-patient component required for a single surgical procedure within a single package, meaning there are fewer packages to open, reduced waste in the OR36, and less risk for contamination37. The all-in-one convenience of ProcedurePak also allows for a faster OR set-up, which contributes to an overall reduction in procedure duration, which has also been shown to reduce the risk of SSI.

-

Surgical | 3 min read The hazard of surgical plume

What is surgical plume? Surgical plume is the vaporous plume resulting from surgical intervention involving the use of an electrocautery device on tissue, using a heated surgical instrument to stop bleeding or remove a growth. The resulting plume, or surgical smoke, is a noxious and odorous by-product that contains both organic and inorganic matter. Surgical smoke in the operating room can also obscure visibility into the operative site, which could conceivably lead to greater risk to patient safety. Surgical plume can be carcinogenic and can spread infection. To reduce the risk surgical plume poses, hospitals should introduce surgical smoke evacuation guidelines and introduce surgical safety technologies to safeguard the health of their surgical staff. [Video Section] plume Types of surgical plume The plume falls into two categories, those being chemical and those being bacteriological, of which both have their own health risks. Chemical matter is more likely to be smaller particles, whereas biological matter of larger size particles, however both are potential hazards to health. Surgical plume can contain carbons, hydrocarbons, viral particles, additionally toxic gases, cellular debris, blood borne products, carcinogens and numerous noxious substances like Benzene, Toluene and Formaldehyde. How are healthcare professionals exposed? What is the risk? When thermal energy devices are used, cellular disruption occurs. As a result, this produces a vaporous plume, which rises into the surrounding area and spreads throughout the entire room. The staff are exposed to significant risk levels, which have been likened to cigarette smoking. Some suggest only 1 gram of surgical plume is equivalent in toxicity terms to smoking between 3 to 6 cigarettes1. In the OR, it would be reasonable to suggest that several grams of surgical plume are produced during the average surgical procedure. Based on the assumption during the average working day of 5 operative procedures involving thermal energy, healthcare professionals may be unwittingly exposed to the equivalent of smoking at least 20-30 cigarettes per day. Of course, smoking cigarettes is a lifestyle choice, whereas healthcare professionals would not necessarily choose to be exposed in this manner. Why has there not been more widespread adoption of surgical plume evacuation devices to date? Possibly, a lack of awareness of the dangers present in surgical plume has led to indifference to the need to remove surgical smoke. Also many of these exposure elements may not present until later in life, perhaps beyond the ability to collate data from individuals. Any suggestions therefore of morbidity or mortality due to surgical plume exposure remain subjective. In addition, there have been some limitations in the solutions previously offered. Surgeons have complained that solutions have been ‘too noisy’, causing unnecessary distractions or that the ‘hand switch plume pencils are far too bulky and cumbersome’. Finally, a new solution, that addresses these concerns, is in your hands. [Promotional card] plume