As time management in healthcare, particularly in the surgical field, becomes more important, hospitals are actively looking for more efficiency from fewer resources. One hospital in France achieved significant improvements to operating room efficiency, according to a Mölnlycke ProcedurePak efficiency study.

By implementing surgical procedure trays, European hospitals achieved 40-55% time savings in the operating room, making it possible to carry out more surgical procedures – around 37% more procedures in one hospital in France.

Exploring how to improve operating room efficiency

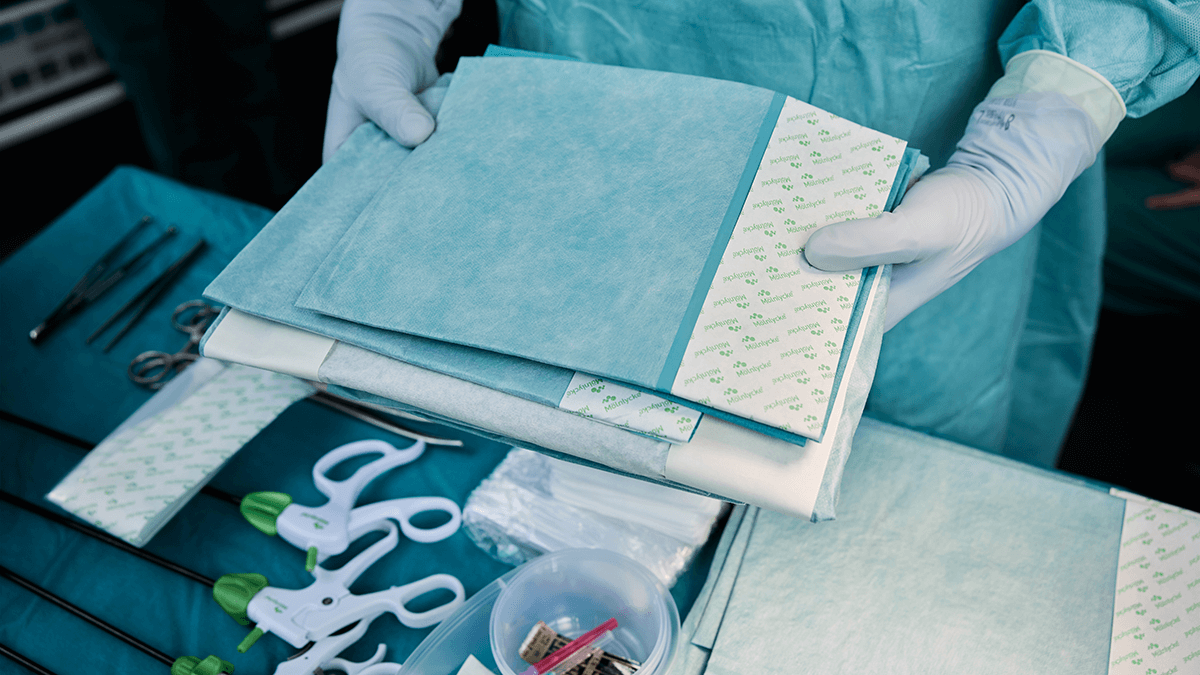

Hospitals in Europe are traditionally supplied with single-packed sterile products for surgical procedures. For each procedure, the nurses in the operating room need to source surgical instruments in the operating room and collect required materials from the storeroom unit by unit and set it all up for each procedure. Other necessary steps to get the right material in place include stock-taking and ordering, as well as warehousing and transportation.

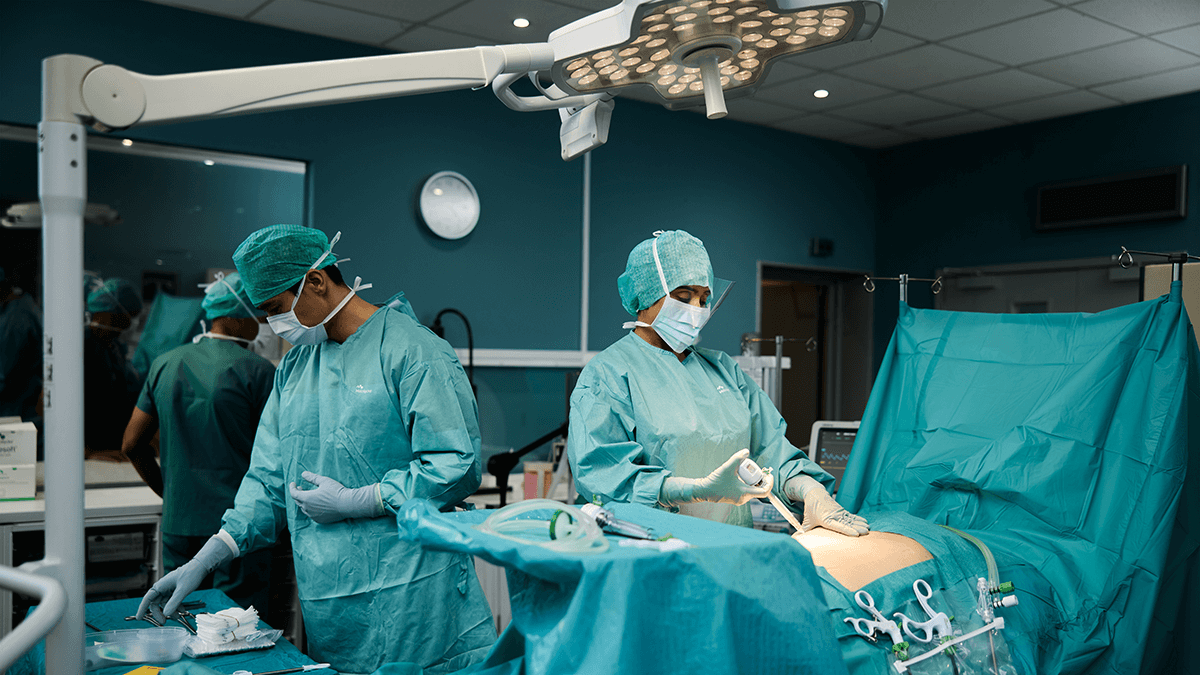

Hospital management today is striving for the most efficient treatment procedures without compromising on quality or safety. Thus there is increasing pressure to handle more interventions while relying on unchanged resources1, 2. Optimising internal processes to improve efficiency has become more and more important, and more effective operating room inventory management, down to the procedure level, has been identified as a way to achieve greater efficiency in the operating room.

Study aim: Quantifying time savings from procedure trays

The aim of the study was to investigate the effects of and quantify time savings when implementing ProcedurePak trays.

Method

This was an open prospective study performed as case studies in different hospitals located in Germany, France and Sweden. A total of 26 different ProcedurePak trays were used. For each of the hospitals the single-use material process was studied, from ordering of materials to disposal. This process typically consists of 6 main processes: internal order and delivery, receiving of goods in the surgical department, preparation and clean-up of surgery, external order, receiving of goods via the purchasing department and invoicing.

The steps can be broken down into sub-processes and activities. For example, the main process – preparation and clean-up – can be broken down into 14 sub-processes or 33 activities. Each step in the process was described and measured both before and after implementation of the Mölnlycke ProcedurePak trays. For every step of the process, the time and cost drivers were identified by studying practical use and measuring time.

Total annual time-saving after implementation of ProcedurePak trays in Germany.

Results: Across hospitals, 40-59% time savings achieved

The results of the study show that following the introduction of ProcedurePak trays, time-savings in the single-use material process were between 40% and 59% in the hospitals studied.

The magnitude of the time-savings depends on several factors, including the number of different ProcedurePak trays used, number of components in each tray and the number of procedures performed with trays. The largest time savings were found in the preparation and clean-up of surgery, which is a key metric for operating room waste management initiatives. But time savings were also shown in other process steps.

The time savings were used in different ways depending on individual objectives of the hospital, for example:

- Performance of additional surgical procedures, giving patients more timely treatment and maximising use of OR resources

- In the French hospital 37% more surgical procedures were performed following implementation.

- In the German hospital the number of interventions increased by 18% per year.

- Training of staff.

Conclusions

The case studies show that significant time-savings (40-59%) can be gained through implementing Mölnlycke customised procedure trays for surgical procedures in the operating room. The freed-up time makes it possible to perform additional surgical procedures. The financial effect of this is an area for further research.