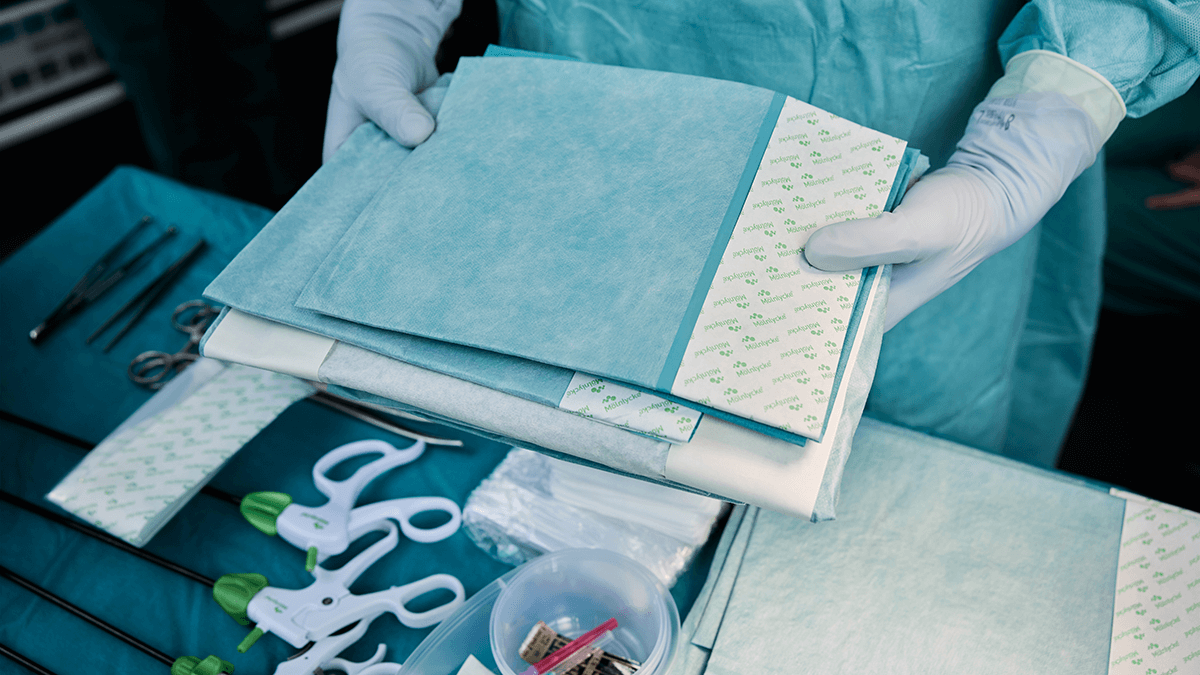

What makes up the most efficient OR workflow? The optimal OR setup involves not only processes and steps that OR staff take but also how they select, store and set up surgical instruments in the operating theatre. The interplay between how people work and the tools they work with influences how OR personnel find their most efficient flow and achieve increased output. The bigger goal is maximising value: gaining more capacity from OR resources at lower costs, with less waste and greater handling efficiency. Flexible OR efficiency Customised surgical procedure trays enable surgical teams to select all the components they need for specific interventions, which are then packed in a single package. The result helps achieve the greater goal of increased safety and efficiency in the operating room, and significant time, money, and waste savings. OR teams that have adopted ProcedurePak customised trays have achieved: Up to 40% reduction in complete preparation time1 Time savings through need for less preparation time, less opening and set-up time, leading to more procedures being carried out – up to a 37% increase in procedures performed1 Reduced packaging leading to less waste2 -- up to 90% less packaging waste2 3, Reduced product spending and logistic costs1,2 – including up to a 54% reduction in invoicing1 Greater accuracy and consistency for every procedure set-up2 The value of end-to-end handling efficiency Savings and efficiency come throughout the handling process – not just inside the OR. From the moment a surgical team configures their procedure-specific tray, through to stocking and handling, to surgery setup, all the way to invoicing and other administrative and procurement activities, every step creates efficiency and savings. These positive outcomes deliver real value you can calculate. For example, you might use your time savings to increase capacity to perform more surgical procedures. Maybe you will use the extra time to run extra OR staff training and education. Potential value-add areas include sustainability (including environmental, social and governance, or ESG), productivity and risk reduction. The value is real – how you claim that value is up to you. OR efficiency value areas: Sustainability Sustainability is a major driver for change in hospitals and in operating rooms, and the ESG agenda is one that organisations aim to derive value from rather than only seeing compliance as a cost. Adding sustainability to operating room efficiency metrics may make up one of the areas of value you can tap into. With customised procedure trays, you can achieve value from both environmental and people considerations. Up to 90% reduction in packaging waste, optimised stock levels and reduced transport are key contributions to environmental improvements. Considering staff needs, getting value from trays and workflows means facilitating improved ways of working, giving OR personnel more time to focus on patients and the things that matter most, and reducing employee stress. ProcedurePak trays simplify OR teams’ work2. OR efficiency value areas: Productivity Every healthcare organisation is under pressure to deliver more with less – safely. Particularly during periods of significant backlogs. How can hospitals reimagine surgical scheduling? Boosting OR capacity and productivity in challenging conditions is a challenge. But up to 70% of OR staff in a UK survey of 500 healthcare professionals4 agreed that customised procedure trays support improvements in operating theatre efficiencies. With ProcedurePak, you can increase the number of procedures you perform by up to 37%1, increasing the capacity of existing OR resources. Procedure-specific trays can also improve cost control per intervention. In more administrative and logistical terms, custom procedure trays can add value by reducing overtime, simplifying invoicing and tracking, and making order and delivery processes smoother and easier. OR efficiency value areas: Risk reduction Healthcare professionals are working under a great deal of pressure, and staff turnover and burnout are significant issues. Working with fewer resources and the requirement to spend substantial time on non-value-adding tasks such as picking and unwrapping individual components and other similar preparatory and clean-up tasks, surgical staff face a number of challenges that can all create risk in the OR. As both surgeons and operating room staff are forced to conduct more procedures with less resources, risk rises. Streamlining the OR workflow with customised surgical procedure trays, though, can contribute to easing staff stress and risk reduction. By requiring fewer packages overall, and saving time and effort in picking, handling, and opening packages, there is less risk of picking errors and less OR foot traffic. These steps lead to increased quality and cost control because the handling and logistics workflow is simplified and more easily managed. Achieving OR efficiency: You’re not alone With Mölnlycke, you’re not alone in starting and accelerating your OR efficiency journey. Taking a consultative approach, Mölnlycke works together with you as a partner to ensure that you achieve the greatest efficiency possible both from adopting ProcedurePak trays and through your OR workflows and practices. Partnership to find your flow and gain greater value How can you reach maximum value and efficiency in your OR? How can you increase output and see time, monetary and environmental impacts? You can influence these factors by finding your flow in the OR. We are here to help. Based on a process designed by the Institute for Workflow Management in Health Care (IWiG) in Germany, we offer a value report based on your specific situation. The report draws on several processes that examine materials management in the OR to help achieve greater time savings and process efficiencies. The value report generated provides an analysis of potential efficiencies and value gains, looking at your current surgical trays and comparing them against ProcedurePak trays customised for specific interventions. With Mölnlycke by your side, you can: Tap into more sustainable processes for both the environment and people/staff, including everything from quantifiably reduced waste and optimised stock levels to reducing staff stress and facilitating more time for focus on patients Protect and increase productivity, increasing the number of possible procedures, improving cost per intervention and simplifying processes Reduce risk, increasing the efficiency of logistics, and cutting down the risk for picking errors, risk due to the handling and opening of more packages and more. With value built in every step of the way, you can increase output with trays – not just in the operating room but throughout the hospital. We can show you how to get there, offering: Partnership in reviewing your current approach, capturing stakeholder insights, defining KPIs, identifying efficiency opportunities, applying expert advice and recommendations and formulating a tailored proposal and implementation plan. Support with evidence-based solutions, regular progress updates and check-ins to ensure opportunities and blockers are identified, full implementation assistance, training and education, and access to the self-serve Mölnlycke Portal. Partnership reviews and performance against KPIs, sharing of best practices, alignment and collaboration with other hospitals. [Card collection] image card link